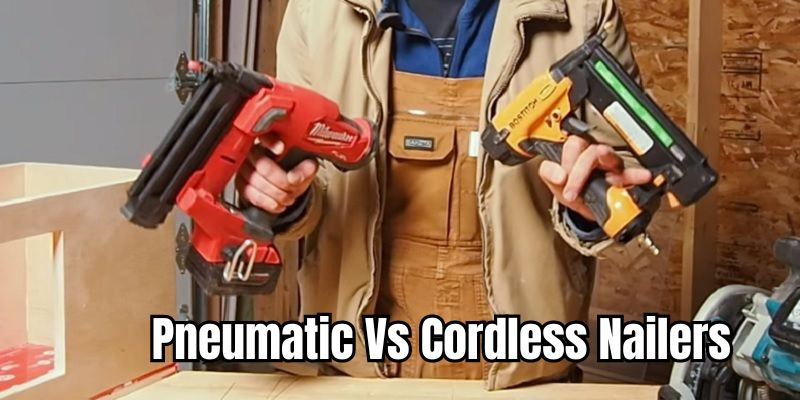

When it comes to choosing the right nailer for your project, understanding the power differences between pneumatic and cordless nailers is crucial. Both types of nailers have their unique advantages and disadvantages, and selecting the one that best suits your needs can make a significant difference in the efficiency and quality of your work. In this article, we will delve into the world of pneumatic and cordless nailers, comparing their power output, ease of use, and overall performance to help you make an informed decision.

Pneumatic Nailers

Pneumatic nailers, also known as air-powered nailers, have been a staple in the construction and woodworking industries for decades. These tools rely on compressed air to drive nails into various materials, offering consistent power and reliability.

How Pneumatic Nailers Work

Pneumatic nailers are powered by an air compressor, which pressurizes air and sends it through a hose to the nailer. When the trigger is pulled, the compressed air is released, driving a piston that forces the nail into the material. The pressure of the air, measured in pounds per square inch (PSI), determines the power of the nailer.

Advantages of Pneumatic Nailers

Consistent Power Output: One of the main advantages of pneumatic nailers is their consistent power output. As long as the air compressor maintains the required PSI, the nailer will deliver the same driving force with each shot. This consistency is particularly important for heavy-duty applications where a uniform depth and secure fastening are essential.

Suitable for Heavy-Duty Applications: Pneumatic nailers are often the preferred choice for heavy-duty projects, such as framing, roofing, and fencing. Their powerful and consistent performance allows them to drive nails through tough materials like hardwood, concrete, and steel with ease.

Longer Tool Life: Pneumatic nailers are built to withstand the rigors of frequent use. The lack of complex electronic components and the durability of the mechanical parts contribute to their longer tool life compared to cordless nailers. With proper maintenance, a pneumatic nailer can last for many years, making it a cost-effective investment in the long run.

Disadvantages of Pneumatic Nailers

Require an Air Compressor and Hose: The biggest drawback of pneumatic nailers is their reliance on an air compressor and hose. The air compressor needs to be powerful enough to maintain the required PSI for the nailer to function effectively. Additionally, the air hose can be cumbersome to maneuver, especially in tight spaces or when working on ladders.

Limited Mobility: The need for an air hose limits the mobility of pneumatic nailers. The length of the hose determines the range of movement, and moving the compressor around the job site can be inconvenient. This limitation can be particularly challenging for projects that require frequent repositioning or working in remote locations without easy access to power outlets.

Noisy Operation: Pneumatic nailers are known for their loud operation, which can be a concern in residential areas or when working in close proximity to others. The noise generated by the air compressor and the nailer itself can be disruptive and may require the use of ear protection to prevent hearing damage.

Cordless Nailers

Cordless nailers have gained popularity in recent years due to their portability and convenience. These battery-powered tools offer a level of freedom and flexibility that pneumatic nailers cannot match.

How Cordless Nailers Work

Cordless nailers rely on rechargeable batteries, typically lithium-ion, to power a motor that drives the nails into the material. When the trigger is pulled, the motor engages, creating a linear force that pushes the nail out of the magazine and into the workpiece. The voltage and amperage of the battery determine the power and runtime of the cordless nailer.

Advantages of Cordless Nailers

Portability and Maneuverability: One of the most significant advantages of cordless nailers is their portability. Without the need for an air hose or compressor, cordless nailers offer unlimited mobility, allowing you to work anywhere without the constraints of a power source. This portability is particularly beneficial for projects that require moving around frequently or working in tight spaces.

No Need for an Air Compressor or Hose: Cordless nailers eliminate the need for an air compressor and hose, making them easier to set up and use. You don’t have to worry about tripping over air hoses or finding a suitable location for the compressor. This convenience saves time and effort, especially for smaller projects or quick repairs.

Quieter Operation: Compared to pneumatic nailers, cordless nailers operate much more quietly. The absence of an air compressor significantly reduces the noise level, making them more suitable for use in residential areas or when working in close quarters with others. The reduced noise also minimizes the need for ear protection, although it is still recommended for prolonged use.

Disadvantages of Cordless Nailers

Limited Power Compared to Pneumatic Nailers: One of the main drawbacks of cordless nailers is their limited power compared to pneumatic nailers. While cordless technology has advanced significantly in recent years, the power output of cordless nailers still falls short of their pneumatic counterparts. This limitation can be an issue when working with harder materials or thicker workpieces.

Shorter Battery Life and Need for Recharging: Cordless nailers rely on rechargeable batteries, which have a limited runtime before requiring recharging. The battery life depends on factors such as the nailer’s voltage, the type of nails being used, and the frequency of use. Having to stop work to recharge or replace batteries can be inconvenient and time-consuming, especially during longer projects.

Higher Initial Cost: Cordless nailers often come with a higher price tag compared to pneumatic nailers. The cost of the tool itself, along with the batteries and charger, can be a significant investment. However, it’s important to consider the long-term costs, as cordless nailers eliminate the need for an air compressor and the associated maintenance expenses.

Power Comparison When it comes to comparing the power of pneumatic and cordless nailers, several factors come into play. Understanding these factors can help you determine which type of nailer is more suitable for your specific needs.

Factors Affecting the Power of Pneumatic Nailers

Air Pressure (PSI): The power of a pneumatic nailer is directly related to the air pressure supplied by the compressor. Most pneumatic nailers operate between 70 and 120 PSI, with higher pressures providing more driving force. It’s essential to match the nailer’s requirements with the compressor’s output to ensure optimal performance.

Nail Size and Type: The size and type of nails being used also influence the power required from the pneumatic nailer. Larger nails or those with a higher gauge (thicker) require more force to drive into the material. Specialty nails, such as those with a coating or unique head design, may also demand more power.

Factors Affecting the Power of Cordless Nailers

Battery Voltage and Amperage: The power of a cordless nailer is determined by the voltage and amperage of its battery. Higher voltage batteries, such as 18V or 20V, generally provide more power than lower voltage options. The amperage, measured in amp-hours (Ah), indicates the battery’s capacity and runtime. Higher amperage batteries can deliver more power for a longer duration.

Motor Design: The efficiency and design of the cordless nailer’s motor also play a role in its power output. Brushless motors, which have become more common in recent years, offer improved performance and runtime compared to traditional brushed motors. They are more efficient in converting battery power into driving force, resulting in better overall performance.

Pneumatic Vs Cordless Nailer: Typical Power Ranges

Pneumatic nailers typically offer higher power output compared to cordless nailers. The consistent air pressure and the absence of battery limitations allow pneumatic nailers to deliver a strong driving force, making them suitable for heavy-duty applications. Framing nailers, for example, often require a minimum of 100 PSI to drive larger nails into dense materials like hardwood or engineered lumber.

Cordless nailers, on the other hand, have a more limited power range. The power output depends on the battery voltage and amperage, with most cordless nailers operating between 12V and 20V. While these nailers can handle a wide range of projects, they may struggle with thicker materials or larger nails. However, advancements in battery technology and motor design have significantly improved the performance of cordless nailers in recent years.

Pneumatic Vs Cordless Nailer: Real-World Examples

To better understand the power differences between pneumatic and cordless nailers, let’s look at some real-world examples of applications suitable for each type.

Pneumatic Nailers:

Framing: Pneumatic framing nailers are the go-to choice for constructing the skeleton of a building. Their high power output allows them to drive large nails (3-1/2″ to 3-1/4″) into thick lumber with ease, ensuring a strong and stable frame.

Read Also: Best Cordless Framing Nailers

Roofing: Pneumatic roofing nailers are designed to handle the demands of installing shingles and other roofing materials. The consistent power delivery ensures that the nails are driven flush and securely, preventing leaks and maintaining the integrity of the roof.

Fencing: When building fences, pneumatic nailers provide the necessary power to drive nails through tough posts and pickets. The rapid firing and strong driving force make the job quicker and more efficient.

Cordless Nailers:

Trim and Finish Work: Cordless finish nailers are ideal for installing trim, baseboards, and crown molding. Their portability and ease of use make them perfect for maneuvering in tight spaces and achieving precise nail placement.

Furniture Assembly: Cordless brad nailers are commonly used in furniture assembly, as they deliver a fine and discreet finish. The smaller nail size and adjustable depth settings allow for delicate work without splitting the wood.

Read Here: Best Pneumatic Brad Nailers

Small Repairs and DIY Projects: Cordless pin nailers are handy for small repairs and DIY projects. Their compact size and low power output make them suitable for attaching small trim pieces, picture frames, or craft projects without causing damage to the material.

Factors to Consider When Choosing Between Pneumatic and Cordless Nailers

Type of Project and Required Power

The nature of your project and the required power should be the primary consideration when choosing between pneumatic and cordless nailers. If you’re working on heavy-duty tasks that demand high power output, such as framing or roofing, pneumatic nailers are the better choice. For lighter-duty applications like trim work or furniture assembly, cordless nailers offer sufficient power and added convenience.

Mobility and Portability Needs

Consider your work environment and the level of mobility you require. If you need to move around frequently or work in locations without easy access to power outlets, cordless nailers provide the freedom and flexibility you need. However, if your work area is stationary and you have a dedicated power source, the mobility limitations of pneumatic nailers may not be a concern.

Budget Considerations

The initial cost of cordless nailers is generally higher than that of pneumatic nailers. However, it’s important to factor in the long-term costs associated with each type. Pneumatic nailers require an air compressor, which adds to the initial investment and ongoing maintenance costs. Cordless nailers, on the other hand, rely on rechargeable batteries, which need to be replaced periodically. Consider your budget and the frequency of use to determine which option is more cost-effective for your needs.

Maintenance and Long-Term Costs

Pneumatic nailers typically have a longer lifespan and require less maintenance compared to cordless nailers. The mechanical simplicity of pneumatic nailers makes them more durable and easier to service. Cordless nailers, with their electronic components and batteries, may require more frequent maintenance and replacement parts. Factor in these long-term costs when making your decision.

FAQs

Can cordless nailers match the power of pneumatic nailers?

While cordless nailers have come a long way in terms of power output, they still have limitations compared to pneumatic nailers. Cordless nailers are suitable for light to medium-duty tasks but may struggle with thicker materials or larger nails. Pneumatic nailers, with their consistent air pressure, can deliver higher power output for heavy-duty applications.

Are pneumatic nailers more durable than cordless nailers?

Yes, pneumatic nailers are generally more durable than cordless nailers. The mechanical simplicity of pneumatic nailers makes them more resilient to wear and tear. They have fewer electronic components that can fail over time. With proper maintenance, pneumatic nailers can last for many years, making them a cost-effective investment in the long run.

What are the best brands for pneumatic and cordless nailers?

Some of the top brands for pneumatic and cordless nailers include:

- Bostitch

- DeWalt

- Hitachi (now known as Metabo HPT)

- Makita

- Milwaukee

- Paslode

- Porter-Cable

- Senco These brands offer a wide range of nailers with varying power levels, features, and price points to suit different needs and budgets.

How do I maintain my pneumatic or cordless nailer for optimal performance?

To maintain your pneumatic or cordless nailer for optimal performance, follow these tips:

- Clean the nailer regularly, removing any debris or dust from the magazine, nose, and trigger.

- Lubricate the nailer according to the manufacturer’s recommendations to keep the moving parts working smoothly.

- Check and replace worn or damaged parts, such as O-rings, seals, or bumpers, to prevent air leaks or misfires.

- Store the nailer properly in a dry, cool place away from direct sunlight and moisture.

- For cordless nailers, maintain the batteries by charging them fully and storing them in a cool, dry place when not in use.

- Follow the manufacturer’s guidelines for recommended nail sizes, types, and operating pressure (for pneumatic nailers) to ensure the best performance and longevity of your tool.

Final Thoughts

When deciding pneumatic vs cordless nailers, consider the type of project you’ll be working on, your mobility requirements, budget, and long-term maintenance costs. If you prioritize power and durability for heavy-duty tasks, a pneumatic nailer is the way to go. If portability and convenience are your main concerns for lighter applications, a cordless nailer is the better choice.

Ultimately, selecting the right tool for the job is crucial for achieving the best results. By understanding the power differences and advantages of each type of nailer, you can make an informed decision that will enhance your productivity and the quality of your work.