Rusted screws can be a frustrating problem for DIY enthusiasts, homeowners, and maintenance professionals alike. Whether you’re dealing with standard screws, headless screws, or trying to remove rusted screws from a license plate, knowing how to effectively tackle these challenges is an essential skill. This comprehensive guide will explore various methods and tools to help you successfully remove rusted screws, providing step-by-step solutions for even the most stubborn cases.

Understanding Rusted Screws

Before diving into the removal process, it’s crucial to understand what rust is and how it affects screws. Rust is a form of iron oxide that occurs when iron or steel is exposed to moisture and oxygen over time. This chemical reaction weakens the material, making it brittle and difficult to remove. Some materials, such as carbon steel and iron, are more prone to rusting than others, like stainless steel or brass.

Leaving rusted screws unattended can lead to a host of problems. As the rust progresses, it can cause the screw to seize in place, making removal even more challenging. Additionally, the rust can spread to the surrounding material, leading to structural damage and compromising the integrity of the object.

Tools Required to Remove Rusted Screws

To successfully remove rusted screws, you’ll need the right tools for the job. Here are some essential items to have in your toolkit:

Screwdrivers: Having a variety of screwdrivers suitable for rusted screws is crucial. Consider using a manual impact driver or a screwdriver with a strike cap to apply extra force when needed.

Locking Pliers and vice grips: These tools can help you grip the screw head or shaft, providing additional gripping headless screw removal.

Dremel Tool: For creating new slots in headless screws.

Drill with extractors: A drill equipped with screw extractors can be a lifesaver when dealing with severely rusted or broken screws.

Heat sources: A blowtorch or heat gun can be used to apply heat to the screw, helping to break the rust bonds and expand the metal for easier removal.

Penetrating lubricants: Products like WD-40 or PB Blaster can help penetrate the rust and lubricate the screw for easier removal.

Impact driver: For stubborn license plate screws.

Abrasive tools: Sandpaper or a wire brush can be used to remove surface rust and improve grip on the screw head.

Masking tape: For protecting paint when removing license plate screws.

Different Types of Methods for Removing Rusted Screws

1. Penetrating Lubricants Method

One of the simplest and most effective methods for removing rusted screws is using a penetrating lubricant. These lubricants are designed to penetrate the rust and lubricate the screw, making it easier to remove. Here’s how to use this method:

- Apply the penetrating lubricant generously to the rusted screw, making sure to coat the head and shaft.

- Allow the lubricant to penetrate the rust for at least 15-30 minutes, or according to the product instructions.

- Using a screwdriver or pliers, attempt to unscrew the rusted screw. If it remains stubborn, apply more lubricant and allow additional time for penetration.

2. Heat and Cold Method

Applying heat to the rusted screw can help expand the metal and break the rust bonds, making removal easier. Conversely, applying cold can cause the metal to contract, which may also help break the rust’s grip. Here’s how to use this method:

- Using a blowtorch or heat gun, apply heat to the rusted screw for 30-60 seconds. Be cautious not to overheat the surrounding material.

- If using the cold method, apply ice or a compressed air duster to the heated screw to rapidly cool it.

- While the screw is still hot (or cold), attempt to unscrew it using a screwdriver or pliers.

3. Mechanical Methods

When dealing with severely rusted or broken screws, mechanical methods may be necessary. These methods involve using specialized tools to extract the screw or create new threads. Here are some mechanical methods to consider:

Screw extractors: These tools are designed to grip the screw head or shaft and remove it by turning counterclockwise. To use a screw extractor, you’ll need to drill a pilot hole into the center of the screw, then insert the extractor and turn it counterclockwise to remove the screw.

Drilling and tapping: If the screw is completely seized or broken, you may need to drill it out and tap new threads. Start by drilling a pilot hole into the center of the screw, then use a larger drill bit to remove the screw completely. Finally, use a tap and die set to create new threads in the hole.

Impact drivers: An impact driver delivers strong, sudden rotational force to the screw, helping to break the rust bonds and remove the screw. Manual impact drivers are a great option for stuck screws, while powered impact drivers offer even more torque for the toughest cases.

4. Chemical Methods

In some cases, chemical rust removers can be effective in breaking down the rust and making screw removal easier. Here’s how to use chemical methods:

- Apply the rust remover according to the product instructions, making sure to wear protective gloves and work in a well-ventilated area.

- Allow the rust remover to penetrate and break down the rust for the recommended time.

- Using a screwdriver or pliers, attempt to remove the screw. If necessary, use a wire brush to remove any remaining rust.

Homemade rust removal solutions can also be effective. One common recipe involves mixing equal parts white vinegar and salt, then applying the paste to the rusted screw and allowing it to sit for several hours before attempting removal.

How to Remove Rusted Screws with No Head

Removing rusted screws with no head can be particularly challenging, but with the right techniques, it’s still possible. Here are some effective methods:

1. Screw Extractor Method

• Use a drill to create a small pilot hole in the center of the headless screw.

• Insert a screw extractor into the hole, turning it counterclockwise.

• As the extractor bites into the screw, continue turning until the screw comes out.

2. Cutting a New Slot

• Use a Dremel tool with a cutting disc to cut a new slot across the top of the screw.

• Once the slot is deep enough, use a flathead screwdriver to turn the screw.

3. Locking Pliers Technique

• Grip the remaining shaft of the screw with locking pliers or vice grips.

• Turn the pliers counterclockwise to remove the screw.

4. Welding Method (for metal surfaces)

• Weld a nut onto the remaining screw shaft.

• Once cooled, use a wrench to turn the nut and remove the screw.

Remember to apply penetrating oil and allow it to soak before attempting these methods. If all else fails, you may need to drill out the entire screw and re-tap the hole.

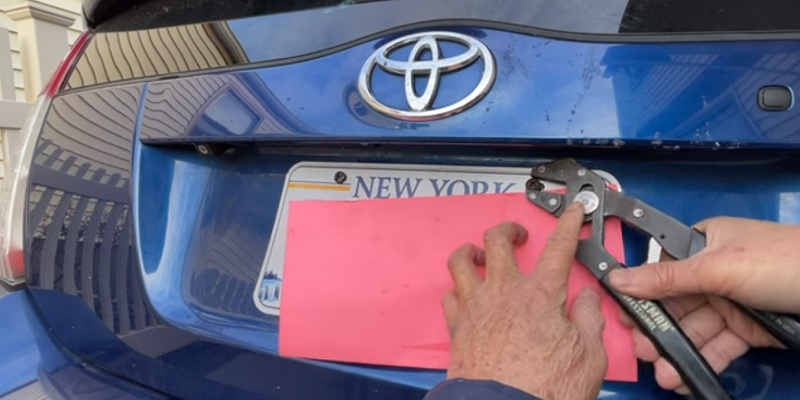

Removing Rusted Screws from License Plates

Removing rusted screws from license plates requires extra care to avoid damaging the plate or your vehicle’s paint. Follow these steps:

Step 1: Preparation

• Clean the area around the screws to remove dirt and debris.

• Apply masking tape around the license plate to protect the vehicle’s paint.

Step 2: Apply Penetrating Oil

• Generously apply a penetrating oil like WD-40 or PB Blaster to the rusted screws.

• Allow the oil to penetrate for at least 15-30 minutes, or longer if possible.

Step 3: Attempt Removal

• Use a screwdriver that fits the screw head perfectly to avoid stripping. If stripped, don’t worry; read here how to remove a stripped screw.

• Apply firm, steady pressure while turning counterclockwise.

Alternative Methods

• If the screwdriver doesn’t work, try using an impact driver for more torque.

• For severely rusted screws, consider using the heat method described earlier, but be extremely cautious to avoid damaging the license plate or paint.

Dealing with Broken Screws

• If a screw breaks, you may need to remove the license plate bracket to access the back.

• Use pliers to grip and turn the remaining screw from behind.

Prevention for the Future

• When replacing the screws, use stainless steel or brass screws to prevent future rusting.

• Apply a thin coat of anti-seize compound to the new screws before installation.

If these methods don’t work, or if you’re uncomfortable with the process, consider seeking help from a professional to avoid potential damage to your vehicle.

Safety Considerations

When working with rusted screws, it’s essential to prioritize safety. Always wear protective gear, such as gloves and safety glasses, to prevent injury from broken screws or chemicals. If using heat or chemical methods, work in a well-ventilated area and follow the manufacturer’s instructions carefully.

Tips and Tricks for Success

Removing rusted screws takes patience. Give rust removers plenty of time to work their magic. Don’t rush – it often leads to more problems. If one method doesn’t work, try another. Sometimes you need to mix different approaches to get the job done.

Pick the right tool for the task. A screwdriver that fits the screw head well will grip better and is less likely to slip. For screws with no head, start gently. Try a screw extractor before moving on to tougher methods.

When dealing with license plate screws, put on rust remover many times over a few hours. If a screw breaks, you might need to take off the whole plate holder to reach it from behind. Use tape around the plate to keep your car’s paint safe.

If a screw won’t budge, you can try making a new groove on top with a cutting tool. This gives your screwdriver a fresh spot to grip. In tough cases, you might need to cut the screw head off completely. Be careful not to harm the area around it.

After you’ve removed rusty screws, replace them with ones that won’t rust easily. Put on a thin layer of anti-rust gel before screwing them in. This helps prevent future problems.

Heat can help loosen screws, but be careful around plastic parts or paint. If you’re working on something valuable or important, it’s okay to ask for help from an expert if you’re stuck.

Remember, taking your time and being persistent is key when dealing with rusty screws. Stay safe and be ready to change your plan if needed.

Some FAQs

How long should I let penetrating oil sit on a rusted screw?

It’s best to let penetrating oil sit for at least 15 to 30 minutes. For really stubborn screws, you might want to leave it overnight. Some people even apply the oil over several days for tough cases. The longer you can wait, the better chance you have of loosening the rust.

Can I use household items to remove rusted screws if I don’t have special tools?

Yes, you can try some home remedies. A mix of vinegar and salt can help break down rust. Coca-Cola can work too because of its acidity. For grip, try putting a rubber band between your screwdriver and the screw head. You can also use hot water to expand the metal slightly. While these methods might not be as strong as special rust removers, they can help in a pinch.

Remember, home methods might take longer and may not work for very stuck screws. But they’re worth a try before buying special tools.

Can I use a drill to remove a headless rusted screw?

Yes, you can use a drill to create a pilot hole for a screw extractor, which can then be used to remove the headless screw.

How can I prevent damaging my car’s paint when removing rusted license plate screws?

Use masking tape around the license plate to protect the paint, and avoid using excessive force or heat near the painted surfaces.

What’s the best tool for removing rusted screws from a license plate?

A well-fitting screwdriver or an impact driver usually works best. Always apply penetrating oil first and allow it to soak.

Conclusion

Removing rusted screws, whether they’re headless or on a license plate, can be a daunting task. However, with the right tools, techniques, and patience, it’s a challenge that can be overcome. By understanding the nature of rust, selecting the appropriate removal method, and prioritizing safety, you’ll be well-equipped to tackle even the most stubborn rusted screws. Remember to take preventive measures to keep your screws rust-free in the future, especially for exposed areas like license plates.

If you have any questions or feedback about this guide or your own experiences with removing rusted screws, please don’t hesitate to reach out. Together, we can build a community of DIY enthusiasts and professionals who are ready to tackle any rusted screw challenge that comes our way.