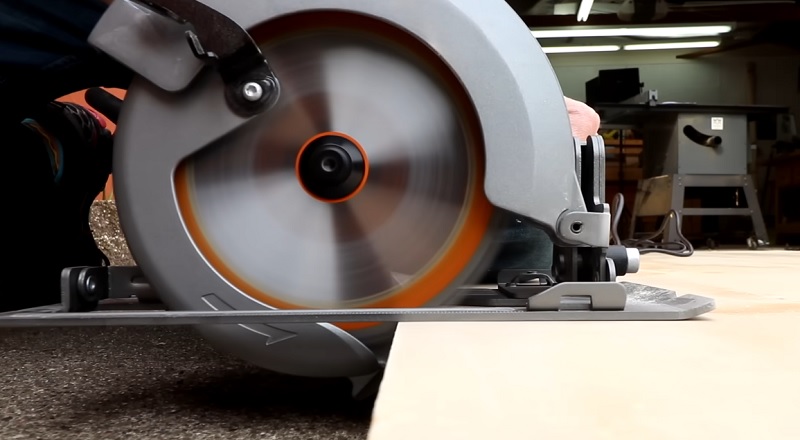

Using a circular saw without a table might sound tricky, but with the right setup and techniques, you can make accurate, clean cuts safely. Whether you’re on a job site or tackling a DIY project at home, these strategies will guide you on using a circular saw effectively without the need for a dedicated table.

Why Would You Use a Circular Saw Without a Table?

Sometimes, a table isn’t available, but that shouldn’t stop you from completing your project. Using a circular saw without a table is common when working on-site, doing outdoor projects, or if you don’t have a large workspace. It’s also useful for quick cuts when setting up a table would take more time than the job itself. With the right method, you can achieve excellent results without a heavy workbench.

Safety First: Preparing for Your Cut

Working without a table requires extra care to ensure your workspace is safe and secure. Here are essential safety tips to follow:

Wear Protective Gear

- Eye and Ear Protection: Always wear safety glasses to protect your eyes from flying debris and ear protection to reduce noise exposure.

- Dust Mask: If you’re cutting wood, wear a dust mask to avoid inhaling sawdust.

Inspect Your Circular Saw

- Check the blade for sharpness and make sure it’s installed correctly.

- Verify that the power cord and any components are in good condition.

Keep Your Work Area Clear

- Ensure that the floor is free from obstructions to avoid tripping.

- Position yourself to the side of the saw, not directly behind it, to avoid kickback.

Following these safety steps is the first essential part of using a circular saw safely, especially without a stable table setup.

Choosing a Stable Surface

While a table isn’t necessary, you will still need a sturdy, flat surface. Here are a few alternatives:

Sawhorses

Using Sawhorses: Place a pair of sawhorses under your workpiece. Sawhorses offer height, stability, and allow for a stable surface similar to a table.

Setting Up the Material: Place the wood across the sawhorses, making sure it’s fully supported and that the blade will clear both sawhorses without cutting into them.

Improvised Workbench

Using a Large, Flat Surface: If you don’t have sawhorses, any flat, waist-high surface can work. Make sure it’s secure and won’t shift under the weight of the wood or the saw.

Tips for Stability: Lay down plywood or a thick board to protect the surface from cuts, especially if using a countertop or another makeshift workbench.

Foam Insulation Boards Method

One practical alternative to traditional supports is using Styrofoam or rigid foam insulation boards (expanded polystyrene foam) as a cutting surface. Place your workpiece on top of a sheet of insulation boards laid on the ground or floor. This setup offers several advantages:

Full Support: The Styrofoam or rigid foam provides continuous support across the entire piece of wood, including the offcut portion, which helps prevent splintering and tearout.

Reduced Kickback: The full surface support minimizes the risk of the blade binding or the wood shifting during cuts.

Simple Setup: For many cuts, especially with larger pieces, the weight of the wood itself on the insulation boards provides enough stability that clamps aren’t always necessary.

Blade Protection: You can set the blade depth just slightly deeper than your material thickness, as the insulation boards will only be minimally damaged by the saw.

Other DIY Options

- Some people use outdoor benches, cement blocks, or even low walls. Just ensure the setup is sturdy and your body is balanced while cutting.

Using any of these surfaces will allow you to make cuts comfortably without a dedicated table.

Securing Your Workpiece

Without a table, it’s crucial to secure your workpiece firmly to prevent it from shifting during the cut. Here’s how to secure it effectively:

Use Clamps: Clamps are essential. Attach the workpiece to your chosen surface with a few clamps. Make sure the clamps are tight but positioned so that they won’t obstruct the path of the circular saw.

Position the Material for the Cut: Arrange the material so that the part you want to cut is hanging over the edge of the surface. This makes it easier to cut through without hitting the support underneath.

Double-Check for Stability: Before you start, give the material a slight push to make sure it’s steady. If it shifts or wobbles, add another clamp or adjust your setup.

Securing the wood is one of the most important steps when working without a table. A stable workpiece will lead to cleaner, safer cuts.

Adjusting Your Circular Saw for Optimal Performance

Once your material is secure, set up your circular saw for the best cut. Here’s what to adjust:

Set the Blade Depth

Adjust the blade depth so it’s just slightly deeper than the thickness of the material. This will make the cut easier and prevent the blade from binding or overheating.

For example, if you’re cutting a 1-inch thick piece of wood, set the blade depth to around 1 1/8 inches.

Choose the Right Blade Type

For smooth cuts, use a fine-tooth blade. A coarse blade may work faster but might leave a rougher edge. Choose based on your project’s needs. Check out best metal cutting circular saw blades for your metal cutting projects.

Check for Blade Alignment

Ensure the blade is straight and not tilted unless you’re planning on making bevel cuts. Misalignment can cause the blade to drift, which is harder to control without a table.

Setting up your circular saw correctly makes a huge difference in the quality of the cut and your overall control.

Cutting Techniques for Precision Without a Table

Using the right cutting techniques will help you get precise results even without a table.

Using a Guide for Straight Cuts

Straight Edge: Place a straight piece of scrap wood or a metal guide along the line where you want to cut. Hold the guide firmly or clamp it in place if possible.

Guide the Saw Along the Edge: Start the saw and guide it along the straight edge slowly and evenly. This helps ensure a straight line without veering off track.

Making Freehand Cuts

Draw a Guide Line: If you’re comfortable with freehand cuts, draw a straight line on the material. Start the saw and follow the line closely, keeping your hands steady.

Maintain a Slow, Steady Pace: Cutting too quickly can cause the saw to drift. A controlled, even speed gives the best results.

Bevel Cuts and Angle Adjustments

Adjusting the Angle: Set the saw’s base plate to the desired angle if you need a beveled cut. For angled cuts, go slowly to maintain control.

Supporting the Material: Ensure the workpiece is well-supported and secure since angled cuts can make it less stable.

These techniques help maintain accuracy, ensuring your cuts are as straight or angled as intended.

Advanced Tips for Improved Precision

If you’re looking for even more precision, here are a few advanced tips to try:

Use Clamps as Guides

Position a clamp along the cut line to act as a rail. This technique is particularly helpful for longer cuts, keeping the saw in place along the line.

Practice on Scrap Material

Practicing on scrap wood helps you get a feel for the saw’s movement, especially if you’re new to cutting without a table. It’s a safe way to improve your skills.

Check for Blade Drift

If your saw tends to drift, you might need to adjust your grip or speed. Practice holding the saw firmly and moving it smoothly along the line.

These advanced techniques are great for honing your skill and improving cut accuracy.

Common Problems and Solutions When Cutting Without a Table

Without a table, you might encounter a few issues. Here’s how to troubleshoot them:

Problem: The cut isn’t straight.

Solution: Use a guide or clamp a straight edge along the cut line.

Problem: The blade binds or stops mid-cut.

Solution: Check blade depth and ensure the wood is properly supported to prevent sagging.

Problem: Sawdust obstructs the line of sight.

Solution: Pause and blow away sawdust or use a saw with a dust blower attachment to keep the line visible.

FAQs:

Can I use a circular saw without clamps?

It’s possible, but using clamps is highly recommended for stability. Without clamps, you’re more likely to experience shifting, which can affect accuracy and safety.

Is a straight edge essential?

For perfectly straight cuts, a straight edge guide is very helpful. For freehand cuts, it’s not essential but can make the process easier.

How do I avoid kickback?

Make sure the blade is set to the right depth, and hold the saw firmly with both hands. Keep the saw’s base flat on the surface and avoid cutting too fast.

Wrapping Up

Using a circular saw without a table is not only doable but can be done safely and accurately with the right approach. By following these tips and taking your time, you’ll be able to make precise cuts without the need for a large workspace or heavy equipment. Just remember to prioritize safety, secure your materials, and practice good technique. Soon, you’ll be comfortable and confident using your circular saw in any setting!