Screws are essential fasteners used in a wide variety of applications, from woodworking and construction to metalworking and electronics. With so many different types of screws available, it can be challenging for beginners to know which one to choose for their specific project.

In this comprehensive guide, we’ll explore the various types of screws, their distinct features, and their intended uses, helping you make informed decisions and achieve successful results in your projects.

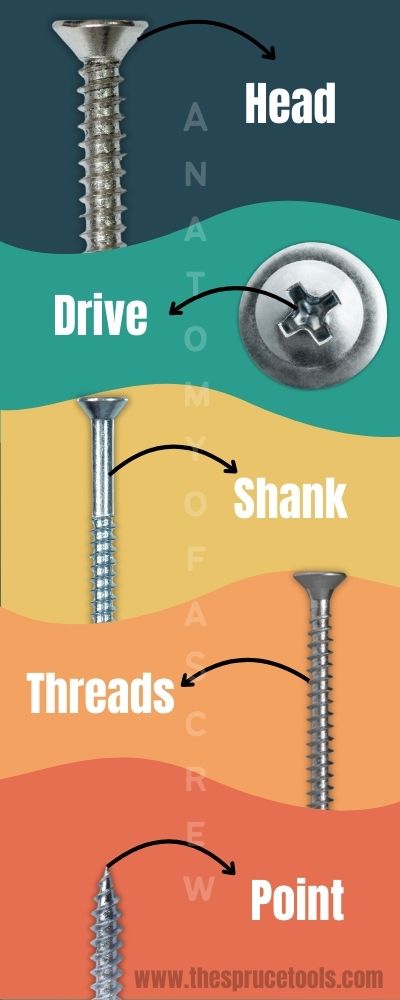

The Basic Anatomy of a Screw

Before diving into the different types of screws, it’s important to understand the basic components that make up a screw. A screw consists of five main parts:

Head: The top part of the screw that is driven by a tool, such as a screwdriver or wrench. The head shape can vary depending on the screw type and intended use.

Drive: The slot, cross, or socket in the head that engages with the driving tool. Common drive types include slotted, Phillips, Pozidriv, and hex.

Shank: The smooth, cylindrical part of the screw between the head and the threads. The shank diameter determines the screw’s strength and the size of the hole it requires.

Threads: The helical ridges that wrap around the shank, enabling the screw to grip and advance into the material. Thread type, pitch, and length vary based on the screw’s purpose.

Point: The tip of the screw that initiates entry into the material. Points can be sharp, blunt, or self-drilling, depending on the application.

Types of Screws

Now that we’ve covered the basic anatomy, let’s explore the different types of screws and their specific uses.

1. Wood Screws

Wood screws are designed for fastening wood to wood and are the most common type used in woodworking and carpentry projects. They feature coarse threads for a strong grip in wood fibers, a sharp point for easy insertion, and a variety of head shapes (e.g., flat, oval, round) to suit different applications. Wood screws are available in various materials, such as steel, brass, and stainless steel, to cater to different environments and aesthetic preferences.

Uses:

- Furniture assembly

- Cabinet making

- Decking and fencing

- General woodworking projects

2. Machine Screws

Machine screws, also known as machine bolts, are designed for fastening metal to metal and are commonly used in machinery, electronics, and automotive applications. They have uniform threads along the entire length of the shank and require a pre-threaded hole or a paired nut for installation. Machine screws are available in various head styles, such as pan, round, flat, and socket cap, and are typically made from steel, stainless steel, or brass.

Uses:

- Assembling metal parts and components

- Securing electronic devices and appliances

- Fastening metal brackets and plates

- Automotive and industrial applications

3. Drywall Screws

Drywall screws, also known as sheetrock screws, are specifically designed for attaching drywall panels to wood or metal framing. They have a bugle-shaped head that tapers at the top to prevent tearing or damaging the drywall paper surface. Drywall screws for wood framing have coarse threads, while those for metal framing have finer threads. They are usually black phosphate coated for corrosion resistance and are available in various lengths to accommodate different drywall thicknesses.

Uses:

- Installing drywall on wood or metal studs

- Securing drywall corners and joints

- Attaching drywall to ceiling joists and furring strips

4. Self-Drilling Screws

Self-drilling screws, also known as Tek screws or self-tapping screws, are designed to fasten materials, particularly metal, without the need for a pre-drilled hole. They feature a sharp, drill-like point that cuts through the material as the screw is driven, creating its own pilot hole. Self-drilling screws often have coarse threads for a strong grip and are available in various head styles and materials to suit different applications.

Uses:

- Fastening metal roofing and siding

- Assembling metal furniture and equipment

- Attaching metal framing and brackets

- HVAC and ductwork installation

5. Concrete Screws

Concrete screws, also referred to as masonry screws or concrete anchors, are used for attaching wood or metal to concrete, brick, or block surfaces. They require a pre-drilled hole and feature aggressive threads that cut into the masonry material for a secure hold. Concrete screws often have a blue coating that provides corrosion resistance and helps with visual identification. They are available in various lengths and diameters to accommodate different load-bearing requirements.

Uses:

- Anchoring wood plates and framing to concrete foundations

- Attaching metal brackets and fixtures to masonry walls

- Securing handrails and guardrails to concrete steps and walkways

6. Cement Board Screws

Cement board screws, also known as backer board screws, are specifically designed for fastening cement board to wood or metal framing in high-moisture areas such as bathrooms and kitchens. They are similar to drywall screws but are made from more durable and corrosion-resistant materials to withstand the demands of wet environments. Cement board screws are available with coarse threads for wood framing and fine threads for metal framing.

Uses:

- Installing cement board as an underlayment for tile installations

- Securing cement board in shower and bath surrounds

- Attaching cement board to subfloors and countertops

7. Deck Screws

Deck screws are engineered for outdoor use and are commonly used in the construction of decks, fences, and other exterior projects. They are made from corrosion-resistant materials such as stainless steel or coated steel to withstand exposure to moisture, chemicals, and extreme temperatures. Deck screws often have a square or star drive head for increased torque and reduced stripping, and they are available in various lengths to accommodate different lumber thicknesses.

Uses:

- Building and repairing outdoor decks and railings

- Constructing wood fences and gates

- Assembling outdoor furniture and play structures

8. Sheet Metal Screws

Sheet metal screws are used for fastening thin metal sheets and are commonly found in applications such as HVAC systems, gutters, and ductwork. They have sharp, pointed threads that can pierce and tap into the metal without the need for a pre-drilled hole. Sheet metal screws are available with self-drilling points for even easier installation and are typically made from steel or stainless steel for strength and durability.

Uses:

- Assembling and repairing HVAC ductwork

- Installing gutters and downspouts

- Fastening metal flashing and trim

- Attaching metal brackets and hardware

9. Lag Screws

Lag screws, also known as lag bolts, are large, heavy-duty fasteners used for securing heavy timbers and lumber in construction and woodworking projects. They have coarse, deep threads that provide exceptional holding power in wood and a hexagonal head that allows for high-torque installation using a socket wrench. Lag screws typically require a pre-drilled pilot hole to prevent wood splitting and are available in various lengths and diameters for different load-bearing capacities.

Uses:

- Constructing timber frames and post-and-beam structures

- Securing ledgers and rim joists in deck building

- Anchoring heavy-duty hardware and brackets to wood

- Assembling outdoor play equipment and swing sets

10. Multi-Purpose Screws

Multi-purpose screws, as the name suggests, are versatile fasteners designed to work with a variety of materials, including wood, drywall, plastic, and light-gauge metal. They often feature a combination of screw characteristics, such as self-drilling tips, coarse and fine thread patterns, and corrosion-resistant coatings, making them suitable for a wide range of applications. Multi-purpose screws are available in various head styles and lengths to accommodate different project requirements.

Uses:

- General home repair and maintenance tasks

- Light-duty framing and carpentry work

- Attaching drywall to wood or metal studs

- Fastening small hardware and fixtures

Choosing the Right Screw for Your Project

With so many types of screws available, it’s essential to select the right one for your specific project to ensure a secure and lasting hold. Here are some factors to consider when choosing a screw:

Material: Consider the materials you’ll be fastening and choose a screw that is compatible and strong enough to handle the load. For example, use wood screws for wood-to-wood connections and machine screws for metal-to-metal fastening.

Environment: Take into account the environment in which the screw will be used. For outdoor projects or areas exposed to moisture, opt for corrosion-resistant screws made from stainless steel, brass, or with protective coatings.

Load-bearing requirements: Assess the weight and stress the screw will need to support. For heavy-duty applications, choose larger diameter screws with deeper threads, such as lag screws or structural screws.

Hole preparation: Determine whether the screw requires a pre-drilled hole or if it is self-drilling. For harder materials or to prevent splitting, pilot holes are often necessary.

Aesthetics: Consider the visibility of the screw head and choose a style that complements the overall look of your project. Some screws, like trim head screws, are designed to be less noticeable.

Common Screw Materials and Finishes

Screws are available in a variety of materials and finishes to suit different applications and environments. Some common materials include:

Steel: The most common and economical screw material, suitable for general-purpose applications. Can be plain, zinc-plated, or chrome-plated for added corrosion resistance.

Stainless Steel: Offers excellent corrosion resistance, making it ideal for outdoor and marine environments. More expensive than standard steel screws.

Brass: Provides good corrosion resistance and an attractive appearance, often used in decorative applications or for fastening brass hardware.

Aluminum: Lightweight and corrosion-resistant, often used in applications where weight is a concern, such as in the aerospace industry.

In addition to materials, screws can come with various finishes that enhance their performance and appearance. Some common finishes include:

Zinc plating: Provides moderate corrosion resistance and a bright, shiny appearance. Often used for indoor applications.

Hot-dip galvanizing: Offers excellent corrosion resistance by coating the screw in a thick layer of zinc. Commonly used for outdoor projects and in marine environments.

Chrome plating: Provides a sleek, polished appearance and moderate corrosion resistance. Often used for decorative purposes or in automotive applications.

Black oxide: Creates a dark, matte finish that offers some corrosion resistance and a subtle appearance. Commonly used in hardware and machinery.

Tools for Working with Screws

To work effectively and safely with screws, you’ll need the right tools. Here are some essential tools for driving and removing screws:

Screwdrivers: Manual hand tools with various tip styles (e.g., flathead, Phillips, Torx) that match the drive type of the screw. They provide good control for light-duty tasks.

Power drills: Electric or battery-powered tools that can drive screws quickly and efficiently. They often have adjustable torque settings to prevent over-tightening or stripping screws.

Check Out: Best Cordless Drill under $100

Impact drivers: High-torque power tools designed for driving large screws and bolts with ease. They deliver rotational and concussive force to drive fasteners effectively.

See Here: High Torque Cordless Impact Driver

Screw extractors: Specialized tools used for removing damaged or stripped screws. They have a reverse thread design that grips the screw and allows for counterclockwise extraction.

When using these tools, always wear appropriate personal protective equipment (PPE) such as safety glasses and work gloves. Ensure the tool bit matches the screw drive type and size, apply steady pressure, and avoid over-tightening to prevent damage to the screw or workpiece.

Final Thoughts

Understanding the different types of screws and their intended uses is crucial for any DIY enthusiast, woodworker, or professional. By selecting the right screw for your project, you can ensure a strong, secure hold and achieve the best possible results. Remember to consider factors such as material compatibility, environment, load-bearing requirements, and aesthetics when making your choice.

With this comprehensive guide, you now have the knowledge to confidently tackle a wide range of fastening applications. Whether you’re building furniture, installing drywall, or working on an outdoor deck, choosing the appropriate screw will make your projects more successful and durable.

FAQs

What is the most common type of screw used in woodworking?

The most common type of screw used in woodworking is the wood screw. It features coarse threads, a sharp point, and a variety of head styles to suit different applications and aesthetics.

Can I use drywall screws for outdoor projects?

While drywall screws are designed for interior use and may not have the necessary corrosion resistance for outdoor environments, some manufacturers offer exterior-grade drywall screws with enhanced coatings that can be used for light-duty outdoor projects. However, for optimal performance and longevity, it’s best to use screws specifically designed for outdoor use, such as deck screws or exterior wood screws.

How do I know if I need a self-drilling screw?

Self-drilling screws are ideal for applications where you need to fasten materials without pre-drilling a pilot hole, particularly when working with metal or hard plastics. If you’re working with softer materials like wood, or if the project requires a high level of precision and control, using a standard screw with a pre-drilled pilot hole may be preferable. Consider the material you’re working with and the specific requirements of your project to determine whether a self-drilling screw is necessary.

By mastering the different types of screws and their applications, you’ll be well-equipped to tackle a wide range of fastening tasks with confidence and skill. Remember to always prioritize safety, use the right tools, and take the time to choose the best screw for your project. Happy fastening!