A washer goes between the screw head and the surface. It helps distribute the pressure and prevent damage.

Understanding where a washer fits is crucial in various projects, big or small. Whether you’re assembling furniture or fixing appliances, knowing the correct placement ensures stability and longevity. Washers play a vital role in reducing friction and securing tightness, making them indispensable in construction and repair tasks.

With the right tools and knowledge, you can enhance the durability and functionality of your projects. This guide will explore the importance of washers and how they work with screws, offering insights into their practical applications. Dive in to learn more about optimizing your DIY or professional projects with effective washer placement.

Credit: diy.stackexchange.com

Choosing The Right Washer

Choosing the right washer for your screw is crucial for a secure and stable fastening. It’s not just about picking any washer—different washers serve different purposes and can significantly impact the durability and performance of your project. Let’s dive into the aspects you should consider when selecting the perfect washer.

Material Considerations

The material of the washer can make a big difference. For outdoor projects, stainless steel washers resist rust and corrosion, ensuring longevity. If you’re working with electrical components, nylon washers provide insulation and prevent conductivity.

Think about where you will be using your washers. Will they be exposed to moisture or chemicals? In such cases, opting for washers made from resistant materials can save you from future hassles.

Have you ever used a washer that rusted away? It’s frustrating and leads to more work. Choosing the right material upfront can prevent these issues.

Size And Thickness

Size matters when it comes to washers. A washer that’s too small won’t distribute pressure effectively, while one that’s too large can look unprofessional and awkward. Measure the diameter of your screw and match it with the appropriate washer size.

Thickness is another factor you shouldn’t overlook. Thicker washers can handle more load and prevent the screw from sinking too deep, preserving the integrity of the material you’re working with.

Have you ever had a screw come loose because the washer was too thin? It’s a common problem, but one easily solved by choosing the right thickness.

Next time you’re staring at a box of washers, consider these factors. What is your project asking of you? The right washer can mean the difference between a project that’s just okay and one that’s built to last.

Credit: www.kenenghardware.com

Types Of Washers

Washers are essential in the world of nuts and bolts. They provide a stable base for screws and bolts. Different washers serve various purposes. Understanding their types can help you choose the right one for your needs.

Flat Washers

Flat washers are the most common type. They spread the load over a larger area. This prevents damage to the surface. They reduce friction between the screw and the surface. Flat washers are ideal for general applications. They come in various sizes and materials.

Lock Washers

Lock washers are designed to prevent loosening. They secure screws and bolts in place. Vibrations can cause screws to loosen. Lock washers prevent this issue. They are often used in machinery. They come in different types like split and tooth lock washers.

Functions Of A Washer

Washers are small, often overlooked components in many assemblies. Yet, their functions are vital. They serve multiple purposes in mechanical connections, particularly with screws. Understanding their role can enhance the reliability and durability of any setup.

Load Distribution

Washers help distribute the load of a screw or nut. This is crucial for preventing damage. Without washers, the pressure concentrates on a small area. This can cause cracks or deformations. A washer spreads the force evenly. Protecting the surface beneath from harm.

Preventing Loosening

Another key role of washers is preventing loosening. Screws may loosen over time due to vibrations. Washers act as a buffer. They reduce the impact of these movements. Keeping the connection tight and secure. Thus, washers help maintain stability in assemblies.

Installing A Washer

Installing a washer with a screw might seem simple, yet it requires precision. A washer helps distribute the load of a screw, preventing damage and ensuring stability. Understanding the correct placement can enhance the durability of your assembly.

Tools Required

- Screwdriver

- Wrench

- Set of washers

- Tape measure

Step-by-step Guide

First, select the right washer for your screw. Ensure the washer fits snugly around the screw. A loose fit can compromise the assembly.

Next, position the washer on the surface where the screw will go. The washer should sit flat against the surface. This provides optimal support.

Insert the screw through the washer and into the designated spot. Tighten the screw using a screwdriver or wrench. Ensure the washer remains in place.

Check the assembly for tightness and stability. A properly installed washer will prevent wobbling or loosening.

Common Mistakes

Placing a washer incorrectly is a common mistake with screws. The washer should be between the screw head and the surface. This ensures stability and reduces the risk of damage. Always check placement for effective assembly.

When assembling something as simple as a piece of furniture or a gadget, using washers and screws might seem straightforward. Yet, common mistakes often trip people up, leading to compromised stability or even potential damage. Understanding these pitfalls can save you time and effort, ensuring your projects are both secure and efficient.Incorrect Placement

One frequent error is placing the washer in the wrong spot. It might seem intuitive to slip a washer on anywhere, but its position is crucial. Washers should generally sit between the screw head and the surface it’s fastening. This placement helps distribute pressure evenly, preventing damage to surfaces. Have you ever tightened a screw only to see the material buckle or crack? Incorrect washer placement might be the culprit. Next time, pause and double-check where you’ve placed the washer before tightening the screw.Wrong Washer Type

Choosing the wrong type of washer is another common misstep. Not all washers are created equal, and using the wrong one can affect the stability of your assembly. For instance, a flat washer is designed to evenly distribute load, while a lock washer prevents loosening. Using a flat washer when a lock washer is needed could lead to screws loosening over time. Think about the specific needs of your project. Does it require a washer that holds tight under vibration? Make sure to match the washer type to your needs. Have you ever wondered why something you assembled came apart so quickly? The wrong washer type might have been to blame. Review the specifications for your project and select the washer that best fits those requirements. A little attention to detail can make a big difference in the longevity and safety of your projects.

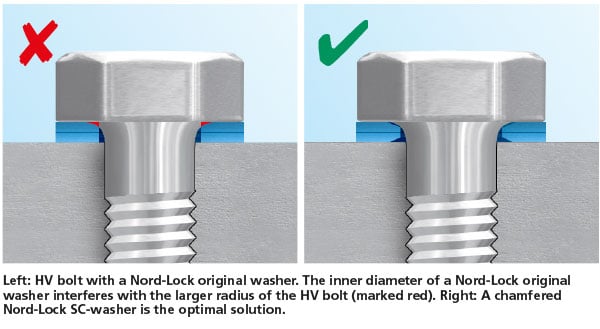

Credit: www.nord-lock.com

When To Use A Washer

Have you ever wondered why washers are paired with screws? Washers are crucial in distributing the load and preventing damage to the surfaces they bind. Knowing when to use a washer can make a difference in the longevity and safety of your projects. Let’s dive into different scenarios where washers are not just helpful, but essential.

Different Applications

Washers find their way into a myriad of applications. From simple home repairs to complex machinery assembly, washers help secure connections effectively. Imagine fixing a loose table leg; a washer can prevent the screw from digging into the wood, ensuring a firm hold.

In automotive or electronic settings, washers are invaluable. They provide the necessary spacing and protection against vibrations. Without washers, screws might loosen over time, jeopardizing the integrity of the whole system. Have you ever tightened a screw only to find it loose a week later? A washer could be the missing piece.

Safety Considerations

Using washers can significantly impact safety. They prevent screws from damaging the surface they’re attached to, minimizing the risk of structural failure. Consider the consequences of a screw pulling out unexpectedly. The washer acts as a barrier, distributing the force evenly.

Additionally, washers can prevent accidental injuries from protruding screws. Imagine the sharp edge of a screw exposed without a washer to secure it. Using washers can be a simple yet effective step to ensure your projects are safe for everyone involved.

Do you think about the potential risks when assembling your DIY projects? A washer might seem insignificant, but it holds the key to security and durability.

Next time you reach for a screw, ask yourself if a washer could make the connection more reliable. It’s a small addition with a big impact.

Washer Maintenance

A washer typically fits snugly with a screw to distribute load evenly and prevent damage. It helps secure the screw tightly and reduces friction. Ensuring proper placement enhances durability and efficiency in appliances.

Maintaining your washer is crucial for its long-term performance and efficiency. A well-maintained washer can help prevent leaks and reduce the risk of damage to other components. Plus, regular checks can save you time and money in the long run. Do you often wonder why your washer gets worn out quickly? Let’s dive into practical maintenance tips to keep your washers in top shape. ###Checking For Wear

Regularly checking your washers for wear can prevent bigger issues down the line. Inspect them for signs of rust, cracks, or deformation. A washer in poor condition can compromise the seal and cause leaks. Make it a habit to check your washers every few months. You might be surprised at how quickly they can wear out, especially in high-use areas like kitchens and bathrooms. If you notice any damage, it’s better to address it sooner rather than later. ###Replacing Damaged Washers

Replacing a damaged washer is a simple and effective way to prevent leaks and ensure a tight seal. If you find a washer that’s worn out or damaged, it’s time to replace it. Keep a few spare washers in your toolbox, so you’re always prepared. To replace a washer, first, turn off the water supply. Then, remove the screw and the old washer. Place the new washer in position and secure it with the screw. This quick fix can prevent potential water damage and extend the life of your appliances. Have you ever thought about how a simple washer could save you from costly repairs? It’s often the small, overlooked components that make a significant difference. Don’t let a worn-out washer cause you unnecessary headaches. Regular maintenance is key.Expert Tips And Tricks

Understanding where a washer goes with a screw can be tricky. But with expert tips and tricks, it becomes easy. Let’s explore key insights. Discover how to choose the right washer. Learn efficient installation techniques. These tips will make your DIY tasks smoother.

Choosing The Best Washer

Not all washers fit every screw. Different screws need different washers. Flat washers are common. They distribute pressure evenly. Lock washers prevent loosening from vibration. Choose based on your project’s needs. Consider the material, too. Stainless steel lasts longer. Plastic washers are lightweight. Match the washer to the screw’s size. A correct fit ensures stability.

Efficient Installation Techniques

Proper installation enhances durability. Place the washer between the screw and surface. This protects the surface from damage. Tighten screws gradually. Avoid over-tightening; it can damage washers. Use a screwdriver or wrench that fits the screw. This prevents slipping and injury. Check for alignment. A misaligned washer can cause instability. Ensure all components are secure. Regular checks help maintain performance.

Frequently Asked Questions

Where Do Washers Go On Screw Nuts?

Washers go between the screw head or nut and the surface. They distribute pressure evenly and protect surfaces. Always place washers flat against surfaces for optimal performance. Ensure the washer size matches the screw or nut for best results. This helps in preventing damage and securing fastenings effectively.

When To Use A Washer With A Screw?

Use a washer with a screw to distribute pressure and prevent damage. It helps secure loose joints and improves stability. Washers are essential for uneven surfaces or when using soft materials. They also reduce friction, ensuring a tight fit and preventing screw loosening over time.

Do Washers Go Shiny Side Up Or Down?

Place washers with the shiny side facing up. This reduces friction and provides a smoother surface. Shiny surfaces are often more resistant to wear. Always ensure proper alignment for optimal performance.

What Is The Order Of Washers And Bolts?

Place the washer between the bolt head and the surface. This helps distribute pressure and prevent damage. Tighten the bolt securely for optimal performance.

Conclusion

Understanding where a washer goes with a screw is crucial. It ensures a secure connection. Washers distribute the screw’s pressure evenly. Prevents damage to materials. Helps in achieving a tight fit. Avoids loosening over time. Place the washer between the screw and the surface.

It’s simple yet effective. A small step that makes a big difference. Always remember this vital detail. Your projects will benefit greatly. Proper use of washers enhances durability. Gives peace of mind. Next time, check your screw and washer placement.

It matters more than you think. Keep your work reliable and strong.