As a DIY enthusiast or professional, you may have wondered whether an impact driver, known for its powerful screw-driving capabilities, can also be used for drilling holes.

In this comprehensive guide, we’ll explore the possibilities and limitations of using an impact driver for drilling, helping you make informed decisions for your projects. While impact drivers are primarily designed for driving screws, they can also be used for drilling in certain situations, with the right accessories and techniques.

Understanding the Difference Between Impact Drivers and Drill Drivers

To answer the question of whether you can drill with an impact driver, it’s essential to understand the key differences between impact drivers and drill drivers.

Drill drivers are designed for both drilling holes and driving screws. They have an adjustable chuck that can accommodate various drill bit sizes and shapes, making them versatile tools for a wide range of applications. The torque output of a drill driver is typically lower than that of an impact driver, but it provides more control and precision.

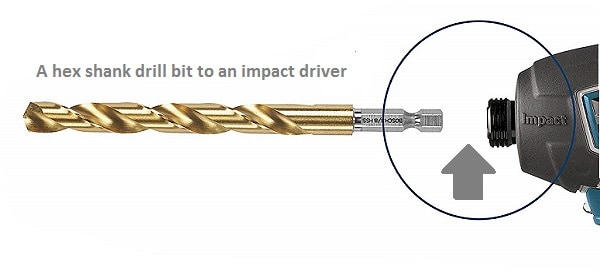

Impact drivers, on the other hand, are primarily designed for driving screws and bolts. They deliver high torque output through a combination of rotational force and concussive blows, allowing them to drive fasteners efficiently, even in tough materials. Impact drivers have a quick-release chuck that accepts only hex shank bits, limiting their compatibility with standard drill bits.

Can You Drill with an Impact Driver?

The short answer is yes, you can drill with an impact driver, but with some limitations. While impact drivers are not primarily designed for drilling, they can be used for this purpose if you have the right accessories and take certain precautions.

To drill with an impact driver, you’ll need to use hex shank drill bits that are specifically designed to withstand the high torque and impact forces generated by the tool. These bits have a 1/4-inch hex shank that fits securely into the impact driver’s quick-release chuck. Regular drill bits with a cylindrical shank will not fit into an impact driver.

Factors to Consider When Drilling with an Impact Driver

When using an impact driver for drilling, there are several factors to keep in mind:

Material Compatibility: Impact drivers are best suited for drilling into softer materials like wood, plastic, and drywall. Drilling into harder materials like metal or concrete may be more challenging and can result in less precise and clean holes.

Drill Bit Size: Impact drivers work best with smaller diameter drill bits, typically up to 1/4 inch. Larger bits may not fit into the chuck or may not perform well due to the high torque output.

Bit Quality: It’s crucial to use high-quality, impact-rated drill bits when drilling with an impact driver. These bits are designed to withstand the intense vibration and prevent premature wear or breakage.

Drill Bits and Necessary Accessories

If you don’t want to buy impact-rated drill bits or if you don’t trust what you see on the internet, you should consider buying an Impact Driver Conversion Chuck. This accessory helps you convert your impact driver to a drill in minutes, and you can easily install it by hand without any assistance.

However, if you don’t have trust issues with buying impact-rated drill bits, we recommend the 9-Piece Impact Tough Titanium Drill Bit Set made by BOSCH. BOSCH is known for producing high-quality accessories for impact drivers and drills, and this basic set is a favorite among home users.

Ultimately, the choice between a conversion chuck and a set of impact-rated drill bits is yours. However, we still advise against using your impact driver as your primary drilling tool. If impact drivers were meant to be the go-to tool for drilling holes, there wouldn’t be so many types of drills available on the market. Before making a decision, ask yourself if you really need to drill with your impact driver, and then choose between the conversion chuck or the drill bit set accordingly.

When to Use an Impact Driver for Drilling

Now that we know impact drivers can drill holes, let’s discuss when it’s appropriate to use them for this purpose. Impact drivers are best suited for drilling into soft materials like wood and plastic. We tested drilling into a pine 2×4 with a Milwaukee drill bit designed for impact drivers, and it worked, although the holes weren’t as clean as those made by a drill driver.

Impact drivers also excel at drilling smaller diameter holes. If you need to make holes that are 1/4 inch or smaller, an impact driver with the right bit can handle the task efficiently.

In situations where a drill driver is not available, and you only have an impact driver, it can be used for drilling as long as you have the appropriate hex shank bits. It may not be the ideal tool for the job, but it can get the work done in a pinch.

Limitations of Using an Impact Driver for Drilling

While impact drivers can drill holes, there are some limitations to keep in mind. We advise against using impact drivers for drilling into hard materials like concrete or brick. They may not provide the best results and could potentially damage the tool or the workpiece.

Compared to drill drivers, impact drivers have limited drill bit options. They are designed to work with hex shank bits only, whereas drill drivers can accommodate a wider variety of bit shapes and sizes, making them more versatile.

Another limitation is the reduced control and precision when drilling with an impact driver. We found that impact drivers offer less control and precision compared to drill drivers, which are specifically designed for drilling tasks. This lack of control can result in less accurate and clean holes.

Tips for Drilling with an Impact Driver

If you decide to use your impact driver for drilling, there are some tips to keep in mind to ensure the best results and minimize the risk of damage.

Choose the Right Bit: Always choose the right drill bit for your impact driver. Use impact-rated hex shank bits that are compatible with your tool and suitable for the material you’re drilling into. This will help prevent the bits from breaking or wearing out prematurely.

Start with a Pilot Hole: When drilling larger holes or working with harder materials, we recommend starting with a smaller pilot hole. This will guide the larger bit and reduce the risk of the drill bit wandering or breaking.

Apply Steady Pressure: To ensure a straight and clean hole, maintain a firm grip on the impact driver and apply consistent pressure while drilling. Keep the tool aligned with the drilling direction to prevent angled or misaligned holes.

Adjust Speed Settings: If your impact driver has variable speed settings, we suggest starting with a lower speed when drilling. This will minimize the risk of damaging the material or the drill bit, especially when working with softer materials or delicate workpieces.

When to Use a Drill Driver Instead

While impact drivers can be used for drilling in certain situations, there are times when a drill driver is the better choice.

Related: Best Cordless Drill Under $100

For drilling into hard materials like metal, concrete, or brick, we recommend using a drill driver with the appropriate bits. Drill drivers are designed to handle these tougher materials and will provide better results with reduced risk of damage.

When drilling holes larger than 1/4 inch in diameter, a drill driver with an adjustable chuck is more suitable than an impact driver. The adjustable chuck allows for a wider range of bit sizes, making it easier to tackle larger holes.

If your project requires precise, clean holes or delicate tasks like countersinking, we advise using a drill driver. Drill drivers offer more control and finesse, allowing you to achieve accurate and professional-looking results.

In situations where you need more control and precision overall, a drill driver is the better choice. Its adjustable chuck, variable speed settings, and design make it the preferred tool for most drilling applications.

Frequently Asked Questions

Can an impact driver remove lug nuts?

Yes, an impact driver can remove lug nuts if they are not excessively tight. However, an impact wrench is the more suitable tool for this task.

See Here: Best Cordless Impact Wrench

What is the best impact driver for drilling?

Some of the best impact drivers for drilling include the Bosch GDX18V-1800CB15 (18V) and the Milwaukee M12 FUEL (12V). These tools offer excellent performance and versatility for both driving and drilling applications.

See More: Best Cordless Impact Drivers for powerful and professional use.

Do I need a drill if I have an impact driver?

It depends on your specific needs. If you require precise, clean holes or need to work with larger drill bits and harder materials, a dedicated drill driver is recommended. However, for basic drilling tasks and most screw-driving applications, an impact driver with the right accessories can often suffice.

Final Words

We’ve discovered that impact drivers can be used for drilling holes, although with some limitations and the need for specific accessories. A drill driver is still the preferred tool for most drilling tasks, but an impact driver can be a viable option for drilling small holes in softer materials when needed.

Consider the material being drilled, the hole size, and the available drill bits before using an impact driver for drilling. Follow the tips provided and use appropriate techniques to successfully drill holes with an impact driver when necessary.

Having both an impact driver and a drill driver in your toolkit will give you the versatility to handle a wide range of projects effectively. Choose the right tool for the job and use proper techniques to achieve excellent results in your DIY endeavors.