Concrete anchors are essential fasteners used in construction to secure objects to concrete surfaces. These anchors play a key role in building stability and safety. This guide will cover the different types of concrete anchors, how to choose the right one, and best practices for installation.

Overview of Concrete Anchor Types

Concrete anchors come in three main categories:

#1 Pre-expanded anchors: These anchors are already expanded before insertion into the concrete. They’re often used for light to medium loads.

#2 Unexpanded anchors: These start small and expand once inserted into the concrete. They’re good for heavier loads.

#3 Heavy-duty anchors: Designed for the biggest loads, these anchors offer maximum holding power.

Common Types of Concrete Anchors

Machine Screw Anchors

Machine screw anchors have internal threads that accept machine screws or bolts. They’re used for attaching fixtures to concrete walls or ceilings. To install, drill a hole, insert the anchor, and then screw in the fastener.

Lag Shields

Lag shields are made for lag screws or lag bolts. They’re often used in outdoor settings or for heavy-duty applications. The shield expands as the lag screw is driven in, creating a tight fit.

Strike Anchors

Strike anchors are hammered into pre-drilled holes. As you hammer, the anchor expands, gripping the concrete. They’re quick to install and good for lighter loads.

Plastic Anchors

Plastic anchors, also called wall plugs, are used for light loads in concrete, brick, or drywall. They’re easy to install and come in various sizes for different screw types.

Wedge Anchors

Wedge anchors are strong fasteners for heavy loads. As you tighten the nut, a clip at the bottom expands, wedging the anchor in place. They’re often used in commercial construction.

Sleeve Anchors

Sleeve anchors have a split sleeve that expands as you tighten the bolt. They work well in solid concrete, brick, or block. Sleeve anchors are versatile and can handle moderate to heavy loads.

Drop-In Anchors

Drop-in anchors are pre-expanded and need a special setting tool for installation. They’re flush with the surface when installed, making them good for clean-looking attachments.

Threaded Rod Anchors

Threaded rod anchors allow for adjustable depth. They’re useful when you need to hang something from the ceiling or attach it at a specific distance from the wall.

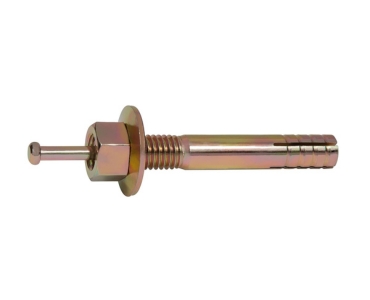

Split Drive Anchors

Split drive anchors are hammered into pre-drilled holes. The split end expands as it’s driven in. They’re quick to install and good for light to medium loads.

Concrete Screws

Concrete screws cut their own threads as they’re driven into a pilot hole. They’re removable and reusable, making them handy for temporary installations.

Factors Affecting Anchor Selection

Choosing the right anchor depends on several factors:

Load Weight: The weight the anchor needs to support is a key factor. Light loads might only need plastic anchors, while heavy equipment requires wedge or sleeve anchors.

Hole Size: The size of the hole you can drill affects your anchor choice. Some anchors need precise hole sizes, while others are more forgiving.

Fastener Length: The thickness of the material you’re attaching and the depth of embedment into the concrete determine the needed fastener length.

Base Material: The type of material you’re anchoring into matters. Options include:

- Solid concrete: Most anchors work well here. Read our guide about how drill into concrete wall.

- Hollow block: Needs special consideration to avoid breaking through the hollow sections.

- Filled block: Similar to solid concrete but may have different strength properties.

- Stone: Can be tricky due to varying hardness and potential for cracking.

- Brick: Anchoring into the brick itself is often stronger than anchoring into the mortar.

- Mortar: Generally weaker than surrounding materials, so avoid if possible.

Read Here: How to drill into brick or mortar?

Seismic Considerations: In areas prone to earthquakes, anchors need to withstand lateral forces. Special seismic-rated anchors may be required.

Installation Process

Proper installation is key to anchor performance:

Drilling: Use the right drill bit size and type. Hammer drills work best for concrete.

Hole Preparation: Clean out dust and debris from the hole. This helps the anchor grip better.

Anchor Insertion: Follow the manufacturer’s instructions for insertion. Some anchors are tapped in, others are screwed in, and some require special tools.

Expansion: For expandable anchors, follow the proper tightening procedure to ensure correct expansion.

Anchor Strength and Performance

Understanding anchor strength helps you choose the right one:

Compression Strength: This is how much squeezing force the anchor can withstand.

Anchor Strength Ratings: Manufacturers provide ratings for pullout strength, shear strength, and tension strength. Always check these against your project needs.

Factors Affecting Performance:

- Concrete strength

- Embedment depth

- Edge distance

- Spacing between anchors

- Environmental conditions (moisture, temperature, etc.)

Corrosion Resistance and Material Options

Choosing the right material for your anchor is important for longevity:

Zinc-plated Anchors: Offer basic corrosion resistance. Good for indoor use or mild outdoor conditions.

Stainless Steel Anchors: Provide excellent corrosion resistance. Best for harsh environments or where moisture is a concern.

The importance of corrosion resistance can’t be overstated. In moist or chemically active environments, corrosion can weaken anchors over time, leading to failure.

Specialized Anchoring Solutions

Some situations call for specialized anchors:

Epoxy Anchors: These use a strong adhesive to bond a threaded rod or rebar to concrete. They’re great for heavy loads and can be used close to edges.

Rebar Anchoring: Sometimes you need to attach new rebar to existing concrete. Special rebar anchors or epoxy systems are used for this.

Structural Engineering Considerations: For critical load-bearing applications, a structural engineer should be consulted. They can specify exact anchor types and placement.

Applications in Commercial Construction

Commercial construction often requires heavy-duty anchoring:

Heavy-duty Anchoring Requirements: Large machinery, structural elements, and safety equipment need reliable, strong anchors.

Compliance with Building Codes: Commercial projects must meet strict building codes. This often means using specific types of anchors and following precise installation methods.

Choosing the Best Concrete Anchor for Your Project

To pick the best concrete anchor for your project, start by assessing your project needs. Consider the load the anchor must support, the environment it will be in, and the base material you’re anchoring into. These factors will guide your initial selection.

For big projects or critical applications, it’s smart to consult experts. Talk to a structural engineer or the anchor manufacturer. They can offer valuable advice and help you make an informed decision based on your specific requirements.

Think long-term when choosing an anchor. Consider future needs and potential changes that might affect the anchor’s performance. It’s often better to go with a stronger anchor than you think you need, as this provides a safety buffer.

Our recommendation for general home use is strike anchors for lighter loads and wedge anchors for heavy loads or commercial projects.

In critical applications, don’t skip testing. Perform a pull test to ensure the anchor meets the required strength. This step can prevent potential failures and ensure the anchor is up to the task.

Finally, always follow the manufacturer’s installation instructions exactly. Proper installation is crucial for the anchor to perform as intended. Even the best anchor can fail if not installed correctly, so pay close attention to the recommended procedures.

Concrete Anchor Safety Tips

Safety is paramount when working with concrete anchors:

Wear protective gear: Safety glasses, gloves, and a dust mask are essential.

Check for hidden hazards: Before drilling, use a stud finder to check for rebar or embedded electrical lines.

Use the right tools: A hammer drill is often necessary for concrete. Don’t try to make do with inadequate tools.

Avoid over-tightening: This can strip the anchor or damage the concrete.

Regular inspections: For permanent installations, check anchors periodically for signs of corrosion or loosening.

Environmental Considerations

The environment where you’re using anchors matters:

Indoor vs. Outdoor: Outdoor anchors need better corrosion resistance.

Chemical Exposure: In industrial settings, consider chemical-resistant anchors.

Temperature Fluctuations: Extreme temperature changes can affect anchor performance. Choose anchors rated for your climate.

Moisture Levels: High-humidity areas need corrosion-resistant anchors.

Anchor Removal and Replacement

Sometimes anchors need to be removed or replaced:

Removal Methods: Some anchors can be unscrewed. Others might need to be chiseled out or cut flush with the surface.

Hole Repair: After removal, the hole might need to be filled before a new anchor can be installed.

Replacement Considerations: When replacing an anchor, you might need to drill a larger hole for a bigger anchor to get the same holding power.

Cost Considerations

Anchor costs vary widely:

Material Costs: Stainless steel anchors cost more than zinc-plated ones but last longer in harsh conditions.

Installation Costs: Some anchors are quick to install, while others need special tools or skills.

Long-term Costs: Cheaper anchors might need replacing sooner, increasing long-term costs.

Quantity Discounts: Buying in bulk can reduce per-unit costs for large projects.

New Developments in Anchor Technology

The field of concrete anchoring is always improving:

Smart Anchors: Some new anchors have built-in sensors to monitor their condition and alert you to potential failures.

Eco-friendly Options: Manufacturers are developing anchors made from recycled materials or designed for easier recycling at end-of-life.

Improved Corrosion Resistance: New coatings and materials are pushing the boundaries of corrosion resistance.

Easier Installation: Innovations are making some anchors easier to install, reducing labor costs and the chance of installation errors.

Common Mistakes to Avoid

Watch out for these common errors:

Using the wrong anchor for the job: This can lead to failure and safety hazards.

Incorrect hole size: Too big, and the anchor won’t grip. Too small, and you might not be able to insert the anchor fully.

Ignoring edge distance: Anchors placed too close to the edge of concrete can cause cracking.

Skipping hole cleaning: Dust in the hole can prevent proper anchor grip.

Over-tightening: This can damage both the anchor and the concrete.

Concrete Anchor Maintenance

Proper maintenance keeps anchors working well:

- Regular Inspections: Check visible anchors for signs of corrosion or loosening.

- Cleaning: For exposed anchors, periodic cleaning can prevent corrosion buildup.

- Retightening: Some anchors may need occasional retightening, especially in high-vibration environments.

- Documentation: Keep records of anchor types, locations, and inspection dates for large installations.

Concrete anchors are a key part of many construction projects. By understanding the different types, how to choose them, and how to install them correctly, you can ensure your projects are safe and long-lasting. Remember, when in doubt, consult with a professional. The right anchor, properly installed, will provide years of reliable service.